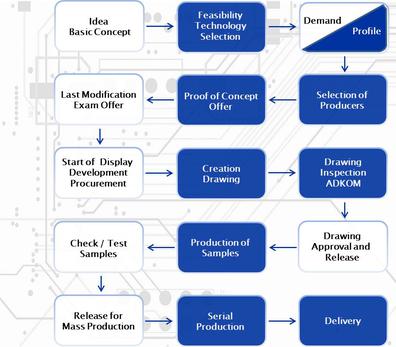

Flow chart for the development steps of a customized display

Focused on LCD-technology ADKOM™ provides a great variety of standard LCD's as well as individual designs in the field of displays and modules. On the following pages you will find information of displays which are technologically and economically feasible as "customized" product. In addition to the in the download area provided checklists for COG modules and LCD displays, we give you important complementary information for the development steps of a custom-designed display.

The advantages of customized Displays are in:

- the specifically to your requirements designed display

- the independence of the respective standards and protocols, which are subject to market

- the sole right to use this display

- the far better long-term availability.

At best, the non-recurring tooling and initial costs can be brought up as disadvantage. This, however, pays for itself rapidly when adjustments to board and housing are going to be necessary.

As your development partner, we would like to show, by way of example, the process of a project.

Rapid Prototyping - 3D-Print enhances service features

For a proof of concept the 3D-Print Technology enables to apply placeholders for display construct for for intricate housing structures in the wide field of development. After drawing approval you can save valuable time until protoypes are ready. In most of the cases CAD-Data for display’s, housings, lightguides or backlights are on hand thus project engineering can be expedited and supply production planning. For the printing process several materials such as PLA or ABS can be applied.

PLA (Polyactide) are synthetic Polymer and most of them are manufactured out of bio components such as corn starch. PLA is hardly inflammable, weatherproof and convinces with low moisture absorption. The surface hardness and stiffness of the printed products is to be classified as good, only the impact hardness of the PLA material is a criteria for mechanical resilience. ABS filament (acrylonitrile-butadiene-styrene) are also a widespread synthetic Terpolymer in 3D printing, which is superior to the aforementioned PLA material in related to heat resistance and surface hardness.

For more Information about, our technic and sales team is available competently.