ADKOMunity II – May 2018

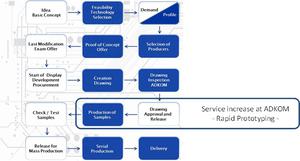

Today again, you will receive news from ADKOM. The initial part of our Newsletter goes in the topic of „Rapid Prototyping“, a proper additional value for our customers who require prototypes for housing design or purpose for production engineering. Modern 3D-Print Technology permits it. On introduction of our team we would like to continue with Andreas Hellwig, however, we are going to start, as above mentioned, with the Desktop Manufacturing Theme.

3D-Print enhances service features

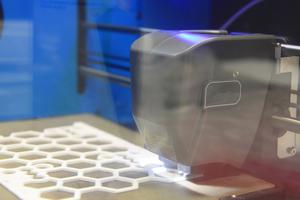

Until some time ago, place holder for a proof of concept have been unimaginable. Thanks to 3D-Print Technology it is possible today. It enables our customers to apply placeholders for display construct or for intricate housing structures in the wide field of development. After drawing approval now you can save valuable time until prototypes are ready when using those printed products.

In most of the cases CAD-Data for displays, housings, lightguides or backlights are on hand at the latest after testing and approval of the product drawing. The time between project engineering of tools until delivery of first functional models can now – using these data – be spent wisely in order to advance the development, respectably, to supply production planning.

For the printing process itself serveral materials such as PLA or ABS etc. can be applied. PLA (Polyactide) are synthetic Polymer and most of them are manufactured out of bio components such as, for example, corn starch. At the same time, it is the most widely used raw material in the filament market. PLA is hardly inflammable, weatherproof and convinces with low moisture absorption, which makes it interesting for many applications. The surface hardness and stiffness of the printed products is to be classified as good, only the impact hardness of the PLA material is insufficient.

ABS filament (acrylonitrile-butadiene-styrene) are also a widespread synthetic terpolymer in 3D printing, which is superior to the aforementioned PLA material in related to heat resistance and surface hardness.

For him ADKOM is a place of challenges

Since November 2014 Andreas Hellwig has been an important and valued member of our ADKOM-team. With emphasis on sales – focused on e-papers - the all-rounder is also head of marketing, press relations and communication. For him ADKOM is a place of challenges and an enterprise worth playing a part in.

His cheerful, open-minded and honest nature is well-received by colleagues as well as customers. Plain and critical he reviews ideas and projects - and if something doesn’t find his approval, he kindly will let you know – and that sooner than later. He has got a cheeky bite and is looking forward to a more cheeky reply.

Besides his communicative and honest character, Andreas Hellwig is setting himself apart by considerable knowledge, experience and willingness to constantly develop and educate himself. Eagerly he faces the rapid pace the world and society are coming along. Just this thoroughly readiness to welcome news with curiosity and demanding a great deal of himself when looking into developing knowledge and technics accounts for expertise he is passing over to corresponding journals. Anyway he prefers to use a slide rule to an electronical display as it is the origin of all developments.

The lust for technique even keeps him occupied in his free time. When not just exploring Wales, rejoicing in all maritime, spending time with the family, he is engaged in historical technology.