ADKOMunity III – June 2018

In the first part of our publication, we give you brief information about AKDOM’S implementation of the GDPR regulations. How to get touch functions on LCMs or COGs? In our second column we introduce you to an alternative, in the form of the in-cell technology.

Important information about our Data Protection Directive

We are very pleased that you are interested in information from our company and that you trust in ADKOM products. For this reason, it is our concern to assure you that we take the protection and security of your personal information very seriously.

On May 25th this year, the EU General Data Protection Regulation, „DSGVO“, entered into force. The purpose of the DSGVO is to set the level of data protection to an uniformly high standard throughout the EU. We had previously set very high standards for our data protection level and were therefore well prepared for the new directive. In addition, we have supplemented our Data Protection Regulation with a few legally required instructions, as well as the handling of your data in the Transparent Information provided in accordance with §12 of the DSGVO.

You can find the latest version of our Data Protection Directive and the Transparent Information on our website.

The adjustments to data protection were automatically implemented by us on May 25th, 2018. That‘s why you don‘t need to do anything else.

Thank you for being one of our customers and potential buyer!

Interaction with Liquid Crystal Displays

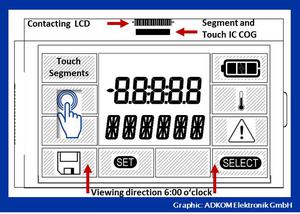

For industrial applications, the „In-Cell“ touch technology, which was introduced by some mobile phone manufacturers, becomes now an interesting alternative to give products a new, and interactive functionality. LC displays can be equipped with capacitive touch buttons without requiring more installation depth for the LCM.

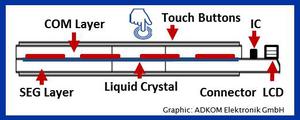

With the In-Cell touch technology, switching elements or silicone buttons, used up to narrow days can be saved and their function be placed on the display element. By using special designed drivers for this technique, a large number of segments are controlled by a single IC. If necessary, the IC can also be cascaded to increase the number of segments even further. For the touch function of the displays, touch buttons are integrated in the COM layer of the upper glasses. This ITO coating is sputtered in cells and is not covering the entire area, as shown in the hereafter following diagram. As a result the interaction area could be placed around the active displayed data area.

Regarding the IC interfaces, the mainly used SPI or I²C busses for smaller display diagonals are offered.

An extended temperature range of up to + 85 °C is similarly available, next to power supplies from 2.5V up to 5.5V. Designed as a low power consumption IC, the technology is as attractive for battery applications as it is for fixed displays in meters.

If you have questions about In-Cell Technology, please contact us.